ÇÖZÜMLER

Rüzgar Enerji

Rüzgar Enerjısı Yenıleme Çözümü

Denız Üstü Rüzgar Enerjısı Çözümü

Karasal Rüzgar Enerjısı Çözümü

Rüzgar Enerji

Rüzgar Enerjısı Yenıleme Çözümü

Denız Üstü Rüzgar Enerjısı Çözümü

Karasal Rüzgar Enerjısı Çözümü

Güç Tüketimi Ve Sektürler

Hafıf Endüstrıyel Makıne

Büyük Deneysel Platformlar

Demıryolu Taşımacılığı

Maden Makıneler

Petrokımya Endüstrısı

Demır Metalurjısı

Güç Tüketimi Ve Sektürler

Hafıf Endüstrıyel Makıne

Büyük Deneysel Platformlar

Demıryolu Taşımacılığı

Maden Makıneler

Petrokımya Endüstrısı

Demır Metalurjısı

ÜRÜNLER

TÜM ÜRÜNLER

Solar İnvertör

Dizi

Merkezi

Eksiksiz PV Çözümü

PV Anahtar Teslim Çözüm

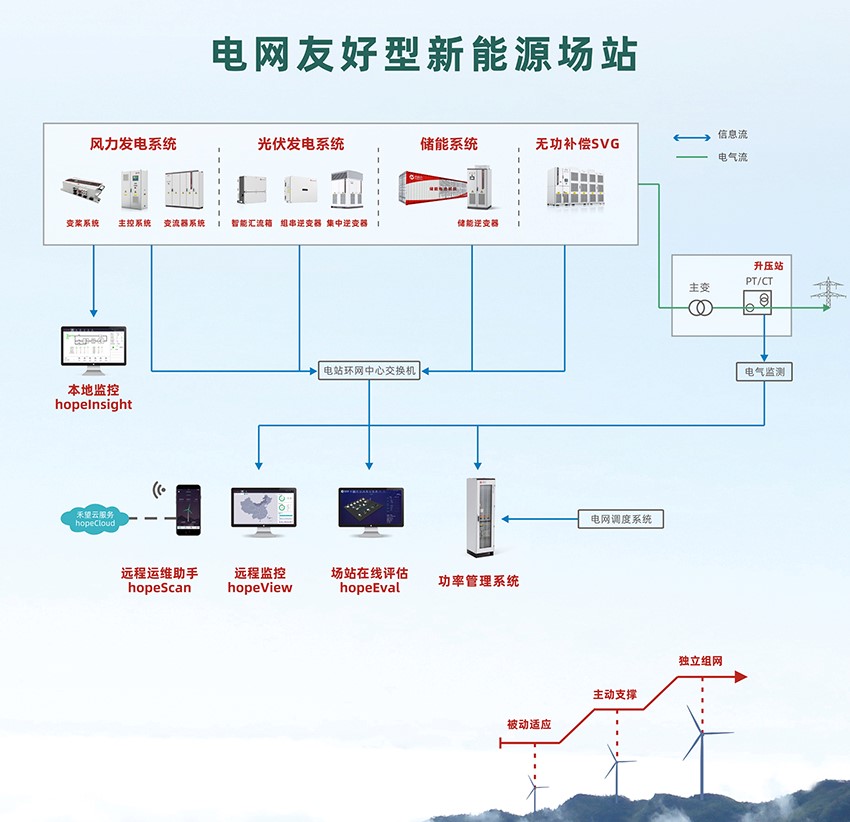

Enerji Depolama Sistemi

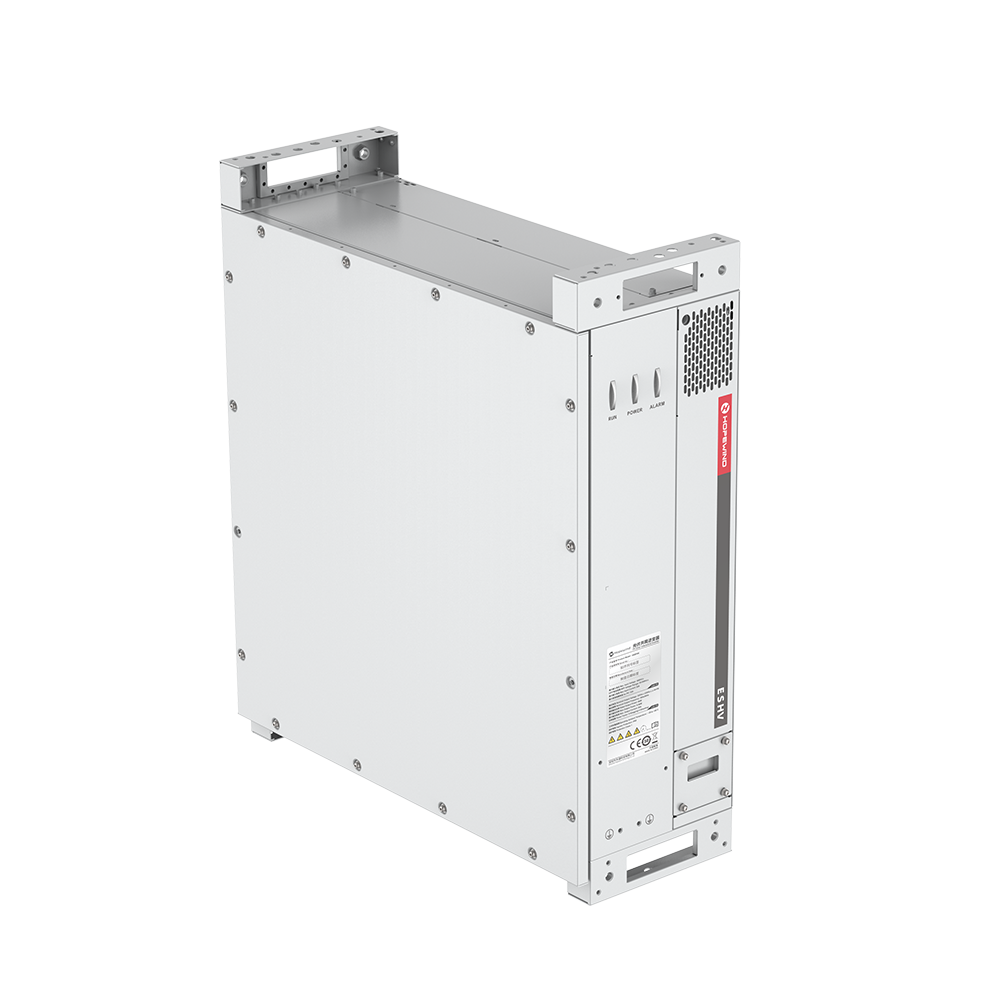

PCS

PCS Taşınabilir Çözüm

Rüzgar Enerjisi Cihazları

Çift Beslemeli Dönüştürücü

Tam Güç Dönüştürücü

Hidrojen Enerjisi

AC/DC tek aşamalı topoloji

AC/DC+DC/DC İki Aşamalı Topolo

Şebeke Simülatörü

AC Kaynağı

VFD

HD8000 Orta Gerilim

HD2000 Düşük Gerilim

HV500

HV300

SVG

10 kV Doğrudan Asılı

35 kV Doğrudan Asılı

Akıllı Uzaktan İzleme Sistemi

hopeEMS Enerji Yönetimi

Français

Français